Zager 3D Printing Blog 🇺🇸

~ The Nitty Gritty of 3d Printing ~

Nov 2024 - Multi-Colored Prints

Up to four colors can be used on a single print if the model is a good quality. The colors are assigned in the slicer and new geometry usually does not need to be created. Silk colors do not work well.

Oct 2024

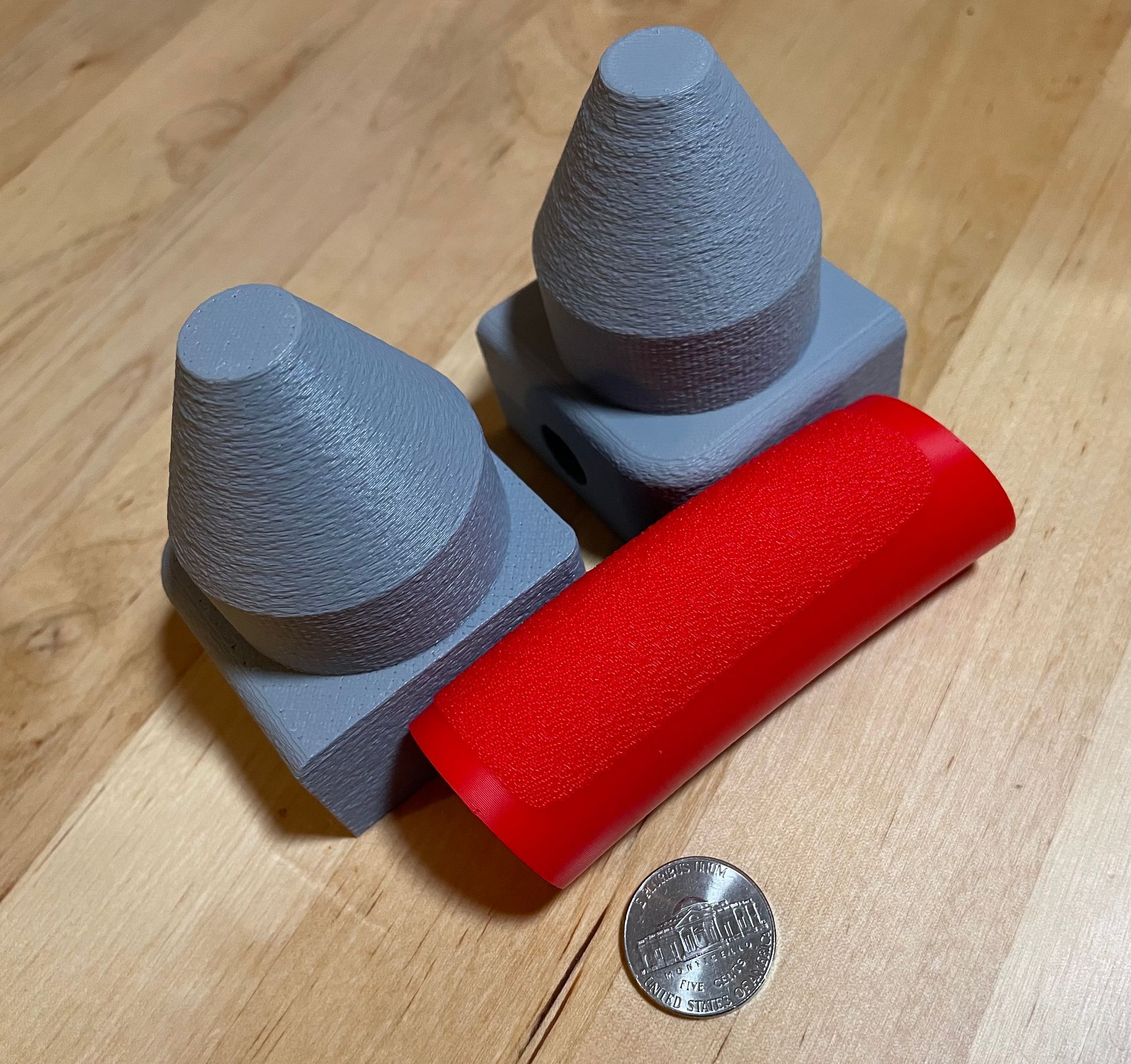

- Textured Prints

Texture can be added to an entire print or just certain areas of a print in order to make the area have more grip and to also hide layer lines. The printing time does go up but not substantially. Many injection molded parts use texture to make the surface more matt and also to hide imperfections along with finger prints.

Jan 2023 - How to Design for 3d Printing

March 2022

- Why are Companies Saying PLA is Brittle 🧐

Many of the bigger 3d printing companies state on their websites that PLA is very brittle as they offer pricier alternatives such as ABS or Nylon. PLA filament can be mixed with other plastics to make it much more flexible and still maintain its strength and is generally called Tough PLA or PLA Plus. I see the reason for the larger companies saying this about PLA is because they have not invested as much in Tough PLA. Tough PLA is a truely remarkable material to print with as it keeps to the dimensions of the part and the surface finish is very smooth. It can be sanded very easily and the supports that are created on it clean up very well. - SH

Jan 2022

- 3d Printing

-

CNC Machining -

Laser Cutting ⌘

3d Printing has gotten a lot of buzz in the last 10 years as being a disruptive technology. 3d printing is totally different from traditional methods of fabrication because it creates by "adding" layer by layer instead of subtracting or cutting. Laser Cutting is useful but it is limited to working with sheets of material. 3d printing can create sheets of different materials so it can do a lot of the same projects. CNC machining has been available for decades and can be very expensive. CNC machining subtracts material from metals or plastics and accomplishes this by switching between different bits and pivoting the toolhead. However, 3d printing can print out a great deal of what used to be CNC Machined. What makes 3d printing so flexible is the way it can switch between materials so easily. In short, 3d printing has become the do-all, swiss army knife of fabricating. - SH

December 2021

- TPU

There are several things to keep in mind when printing with TPU. First is the model needs to be a blocky solid object and not have thin walls. This is because the part will simple vibrate too much during the printing process and not form a solid part. Secondly, the Shore Hardness will partially determine how flexible the part is. We print with 95A Shore which is rather stiff, and the part will feel like a shoe sole. The lower the Shore the more flexible the material. The infill settings will also affect the flexibility and those can be adjusted. The "U" in TPU stands for Urethane which is one of the toughest materials available. Urethane is used to clear coat furniture as well as floors.

I have been asked many times if I can print a flexible silicone mold. The short answer is no as 3d printed parts are not as clean nor as flexible as a Silicone mold. Silicone is extremely flexible and that flexibility is needed to remove the mold from the part. We can print out a clean Master to create a Silicone mold from.

November 2021

- Clear PETG

I have gotten many, many calls asking if clear parts can be printed. The answer is "sometimes". These glow sticks were printed in clear PETG which is the clearest material to print with. It was printed with "one" layer on the outside which makes the parts fairly thin. The glow sticks were still strong as the shape is tubular. If the shape is larger then it may be too weak to use. The layer lines are visible as they are for all 3d printed parts. The parts are durable and can withstand temperatures of 190 degrees F but they looked like they were slightly frosted. When the batteries were inside you could read the brand through the plastic. PETG is the plastic used for making the clear soda bottles found everywhere except it is just PET plastic. - SH

Oct 2021

- PETG with Chopped Carbon Fiber

It has taken many tests but Zager3d can now reliably print PETG with chopped carbon fiber (formerly Nylon). The combination of the two materials is the most remarkable thing. PETG is extremely tough but is somewhat tricky to print. The carbon fibers are light and make the PETG rigid during the printing as well as after. What you end up with is something that can withstand being run over by a car without breaking.